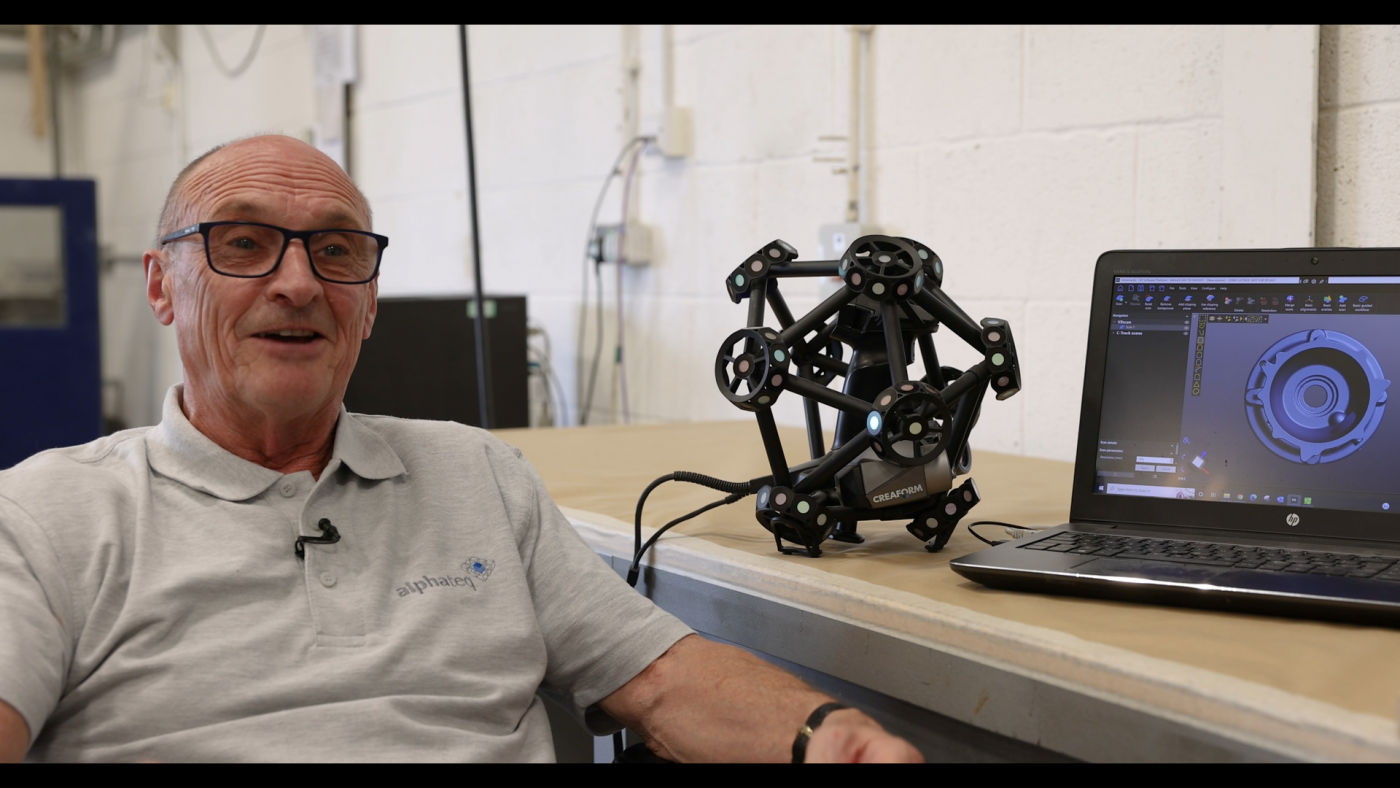

Watch Brian’s interview here:

Brian Garforth

Owner & Managing Director

Brian Garforth is an apprenticeship-served patternmaker with over 50 years’ experience. His first role was for Sterling Metals as a Junior Foreman, in their Magnesium Foundry, but not for long. He soon started setting-up and running his own pattern making businesses, launching Alphateq 20 years ago as the owner and MD.

He’s most proud of the team of skilled engineers he’s assembled, some of whom were originally his apprentices, now in their 50’s, who are still with him today – creating that real family feel. He believes his team are brilliant at taking difficult toolmaking problems, and not only solving them, but offering a superior advisory service that’s measured by their ability to respond to technical challenges, way beyond customer expectations. Working with many Blue-Chip OEM’s across industries such as foundry, automotive, powertrain, aerospace, power supply, carbon fibre, marine and F1, Brian personally uses his extensive knowledge and experience of toolmaking, patternmaking, dies, moulds, and jigs & fixtures to effectively and quickly give the customer a superior product outcome.

Jamie Pedley

Director – Commercial and Technical

Jamie Pedley is an apprenticeship-served patternmaker and CAD designer. Over the last 20 years he’s worked in the foundry, power generation, space, and aerospace industries, and is experienced in producing prototype patterns and castings, CNC machining, and complex project management.

His customer focus is on giving initial technical advice and updating them with honest, timely feedback. Jamie manages the shop floor, tracks the projects, and responds to customers, especially with tight, prototype industry, lead times. His most challenging project was for Aerospace giant, Meggitt, on a huge seal project for an entire aeroplane, working with Bombardier. His experience goes from working with the likes of Zeeko in the space industry, running high-spec optical polishing machines for parts on space telescopes and satellites, to high-tech F1 parts for McLaren, Mercedes-Benz, Haas, and GTR.

Watch Jamie’s interview here:

Paul Welland

Studio Manager

Paul Welland is a patternmaker by trade, completing his apprenticeship in 1971. During those early days his employer had both a foundry and model shop, so he became a highly skilled craftsman in both disciplines. Since then, Paul’s worked all around the world.

His first move was patternmaking in Canada, working on huge components in the mining and logging industries. Returning to the UK, he worked in Aerospace on lost wax moulds. Then off to Sweden model making for Volvo. Next came California working for Northrop on complex Aircraft parts using plaster patternmaking. Paul eventually moved back to the UK working with JLR through the CGI Group, and joined Alphateq in 2006, to use his expertise with the likes of JLR, Tata, and various aerospace companies. He enjoys using his vast array of knowledge and expertise to figure out the most effective way to make all manner of complex engineered parts, with a focus on studio-based life-like prototype models for Automotive and Aerospace interiors and exteriors.

Watch Paul’s interview here:

Watch Tari’s interview here:

Tari Puwar

Toolroom Manager

Tari Puwar is a toolmaker who’s worked in the pattern industry for over 35 years. He has many years of experience in Die Making and Die Design, diligently focusing on each customer’s exacting specification. When he’s not in the toolroom he’s out on-site at customers, with his toolbox in-hand, trouble-shooting their tooling issues.

Having worked with such names as Mercedes-Benz, Williams, McLaren, Grainger & Worrall, JLR, Aston Martin, Rolls Royce, and Meggitt, his skillset is in niche specialist precision engineering work and prototypes. Having worked in many industries like aircraft, automotive, F1, electrical, plastics, and medical, Tari has years of experience and knowledge in patternmaking, injection moulding tools, jigs & fixtures, and press tools and dies of all types. He’s at his best on the bench, putting things together, taking them apart, and leading his team of highly skilled engineers and apprentices doing the same thing.

Ask The Technical Experts

Book your FREE advisory consultation today.

If you’d like to discuss your most challenging engineering and design part or project, with a vastly experienced senior Alphateq engineering specialist, we invite you to book a FREE no-obligation confidential consultation with one or more of the above experts