3D Optical Scanning and Inspection

CREAFORM Metrascan 3D Optical Scanner.

A metrology-grade measurement piece which provides the highest possible levels of product quality control, formal proof of dimensional validation and surface reproduction accuracy.

This delivers real time visualisation of scanned surfaces, accurate (up to 0.030mm) measurement of items ranging in length from 0.2M to 10M and a three dimensional volumetric accuracy of up to 0.064mm.

The Information gathered can be converted directly to a CAD model or to a format suitable for 3D printing or reverse engineering by means of dedicated software.

This portable and lightweight measurements/scanning can be carried out on customers’ own premises too.

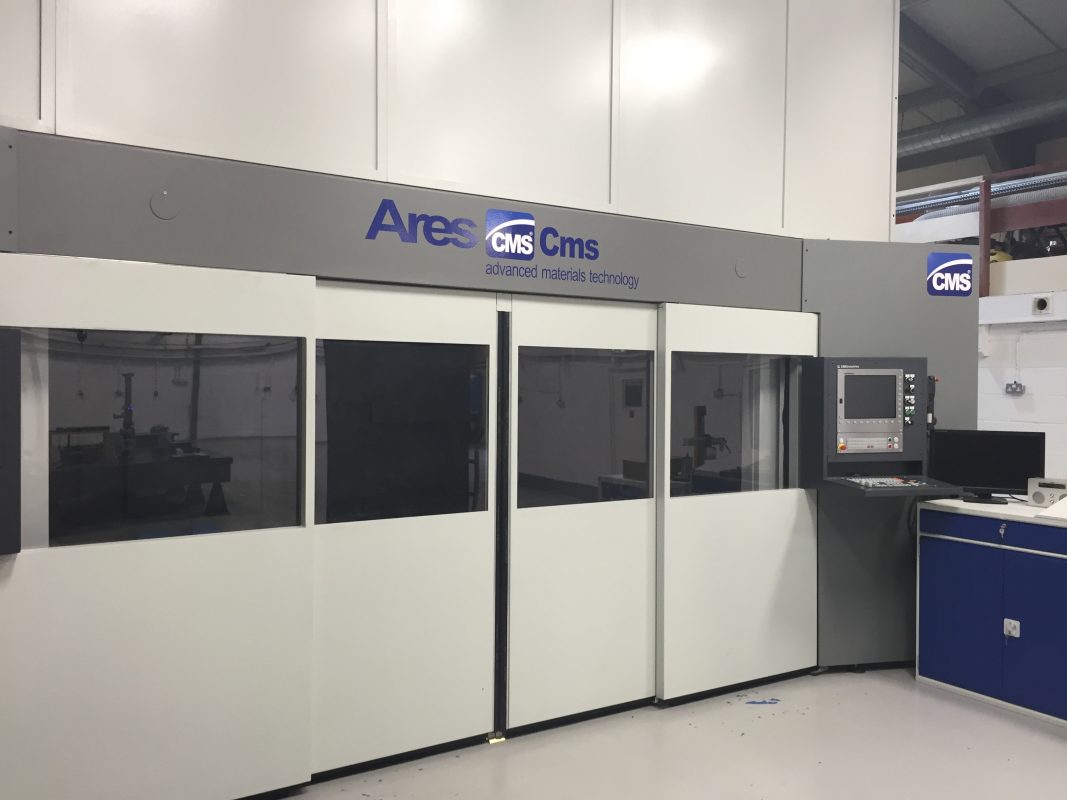

CNC Machining

Alphateq is committed to an ongoing programme of capital equipment replacement and improvement. As a result we currently have at our disposal twenty-five High Speed Machining Centres which between them, together with the use of industry leading Delcam PowerMILL CAM software, allow us to provide 3-axis, 3+2 axis and 5-axis machining with an exceptional degree of surface finish in a variety of materials including: Model Board, Aluminium, Tool Steel and Plastics.

Our investment also extends to a comprehensive range of necessary secondary Machine Tools and other equipment, such as our Agie Charmilles CNC controlled Die-sinking EDM, so that we are able to accept significant orders for major projects without compromising our ability to support the day to day requirements of our Pattern Shop and Tool Room.

All our CNC Machines are operated by skilled technicians, and we run on a flexible, single shift, seven days a week basis, with ‘lights-out’ operation as necessary to meet the lead time requirements of our customers.

At present the largest working envelope we offer is provided by our CMS 5-axis ARES CNC Gantry Operated Machining Centre that has X, Y, and Z values of 3.6M x 2.6M x1.2M respectively.

Supporting this machine is our slightly smaller CMS 5-axis model ANTARES, which has X, Y, Z values of 2.6M x 1.5M x 1.2M. Variable Axis machining (2 x Mazak ‘Variaxis’) for ‘one set-up’ production of complex components. CNC EDM up to 0.6M x 0.4 x 0.4M. Programming in Autodesk Powermill.

Comprehensive range of secondary equipment.

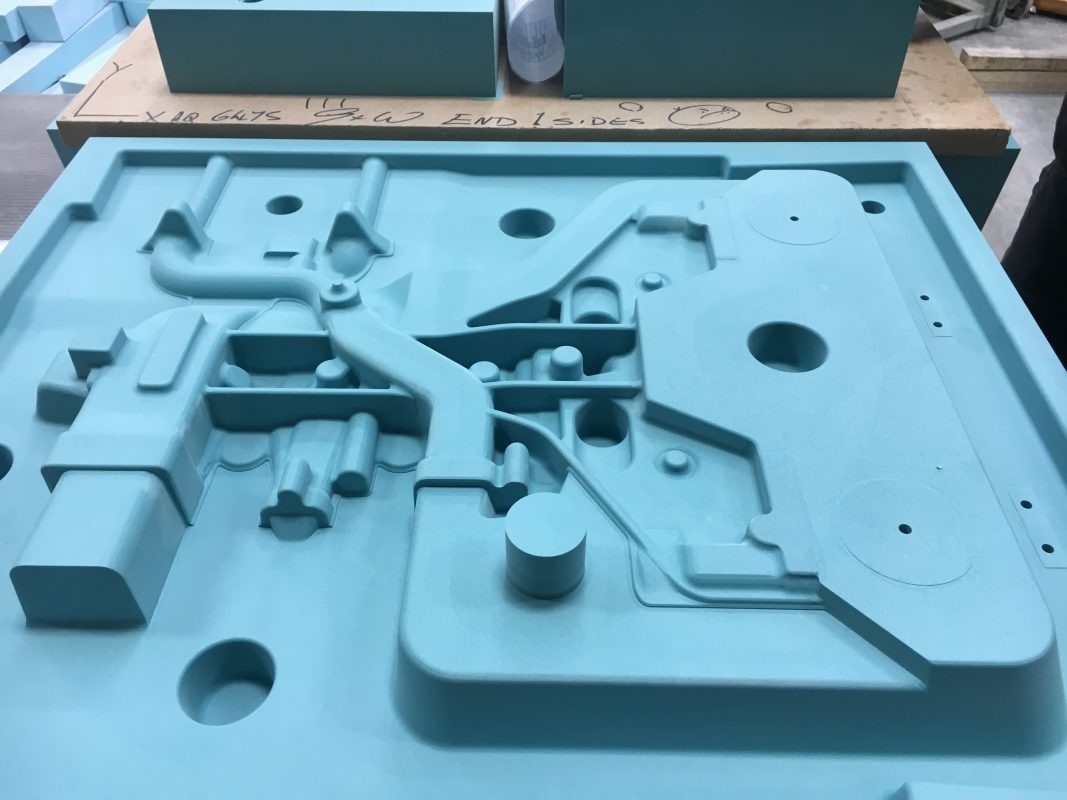

Foundry Tooling

At the core of our philosophy is the belief that second best is never good enough, an ideal that is exemplified by the work produced in our Pattern shop. Primarily manufacturing Patterns for high quality and development Sand Castings in Model Board or Aluminium, but also for the manufacture of Composite moulds, we have a particular expertise in the design and manufacture of Pattern Tooling for Automotive power train applications, specifically Cylinder Heads, Blocks, Transmission Casings and Turbo Housings.

However in all areas of our work, attention to detail is the hallmark of our highly skilled Pattern Makers and Tool Makers.

Foundry Tooling we supply includes: Patterns in Board and Aluminium, Shell Moulds, Gravity Dies and Low Pressure Dies.

Gravity and Low Pressure Dies for both manual and fully automated casting processes are machined and assembled in our Tool-Room, which has its own skilled staff, plant, and equipment.

In order to ensure that the traditional skills of our Pattern Makers and Tool Makers are maintained going forward, Alphateq now operates comprehensive apprenticeship schemes and post-graduate training programmes.

We are always interested in hearing from young people with an interest in Engineering that might wish to apply for a place on one of our schemes at some future date.

For Heritage Vehicle restoration purposes we are able to reverse-engineer many castings so that Patterns for the re-manufacture of engine and transmission components can be produced.

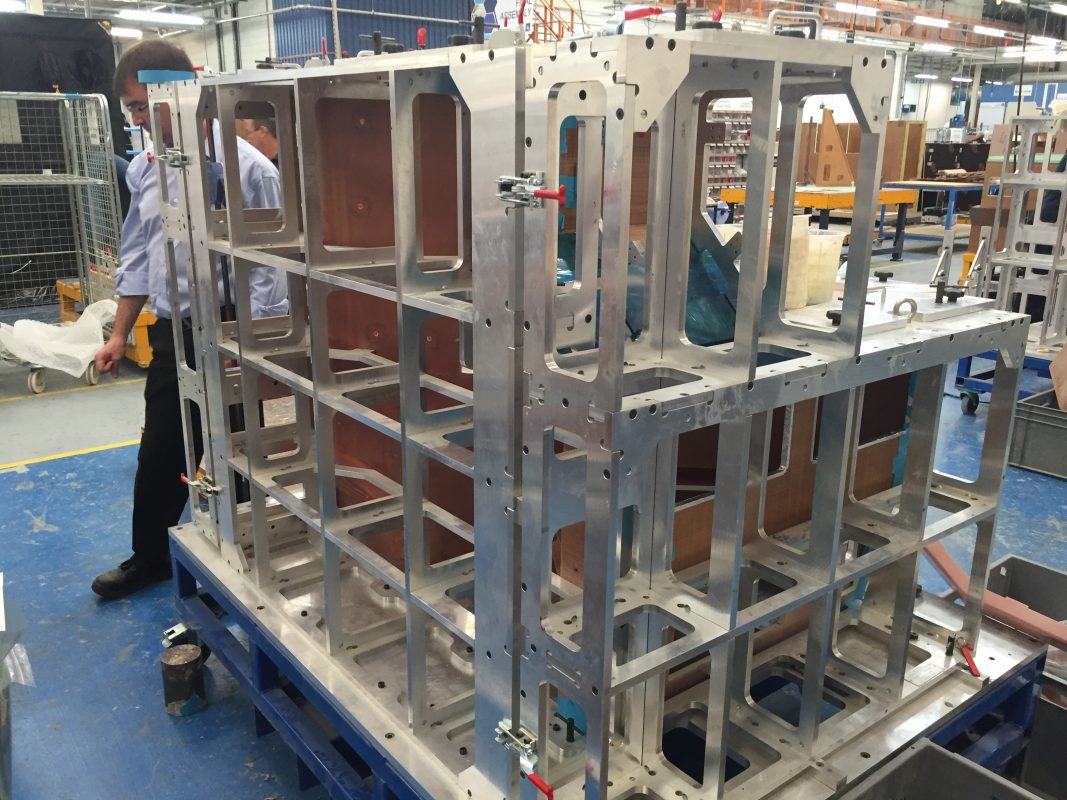

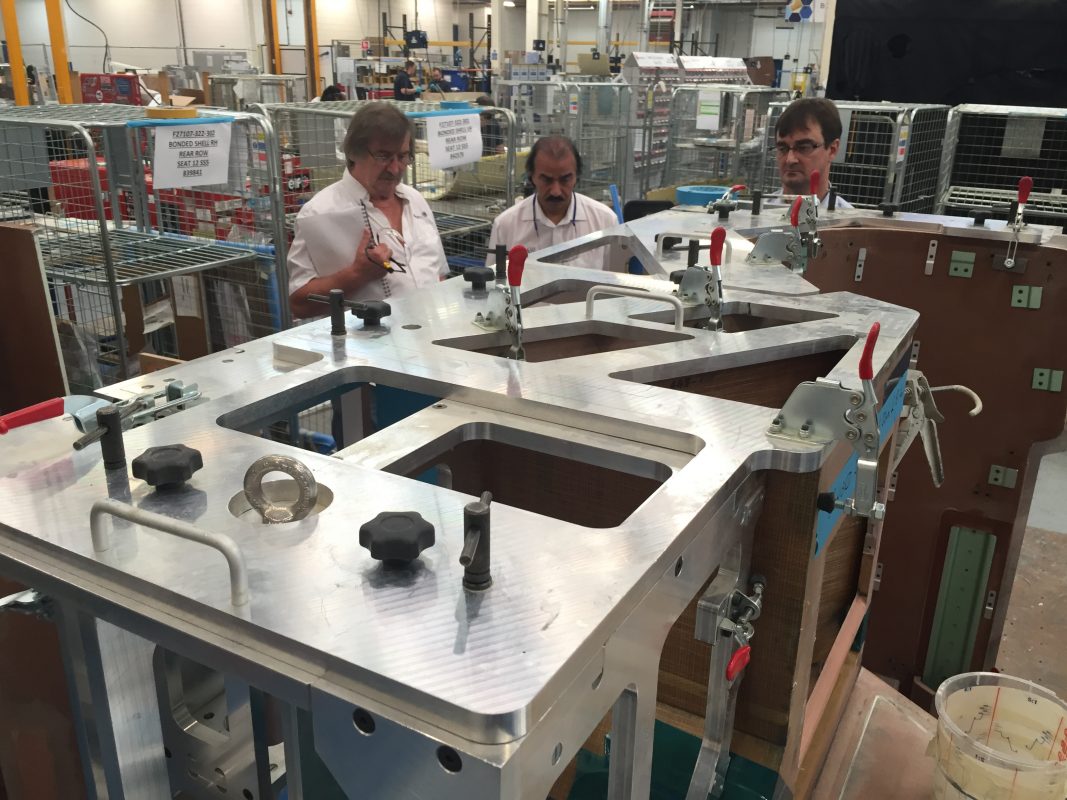

Tooling for Composite Components

Alphateq Ltd designs and manufactures patterns and moulds for a wide range of applications that involve the manufacture of composite components.

We work extensively in areas that include both Automotive (lightweight Carbon Fibre components, GRP, ABS body panels) and Aerospace (Aircraft re-fueling Pods, Antenna Domes, Seating components, Interior panels, and structures etc.)

Tools that we currently manufacture for Composite related applications include: Patterns for the production of composite tools, Hand Lay-up Tooling, Vacuum Forming Tooling, Moulds for Thermo-plastic components, RTM Moulds, Compression (SMC) Moulds, Bonding Fixtures and Assembly Fixtures.

We would welcome enquiries from any marine, commercial or industrial enterprise that requires tooling for the manufacture of composite items, components or structures.

Ask The Technical Experts

Book your FREE advisory consultation today.

If you’d like to discuss your most challenging engineering and design part or project, with a vastly experienced senior Alphateq engineering specialist, we invite you to book a FREE no-obligation confidential consultation with one or more of the above experts

Get in Touch

Model Making and Body Engineering

Alphateq produces models for a wide range of commercial and Industrial purposes. However we are particularly involved in the field of Automotive Development interior and exterior (Body Engineering) Model Making.

In this area it would be fair to say that we have contributed in a small way to the success of some of the most prestigious vehicles that the UK has produced in recent years.

The scope of our work has included: Wind Tunnel Models, Concept models, Partial model stacks, Partial cubes (Feasi-cube, Function-cube, E-cube), Adjustable Local models, Door and other Interior panels, Fascias and consoles, Seating Bucks, Seal Bucks and Clinic Package Bucks.

Specifically, to facilitate this type of work we have allocated a secure section of our factory for automotive development. This area now houses our largest machining centre, fixed and mobile MM equipment and a dedicated projects room.

We have also sunk a steel plate into the floor on which package bucks and similar models can be accurately mounted by means of adjustable pods for set-up/measurement by FARO arm.

For Heritage vehicles, we can reverse-engineer body panels by means of Laser Scanning to produce Hammer Forms for renovation purposes and for the Motorcycle Industry we can supply models for exhibition purposes such as fuel tanks, engine blocks and cylinder heads which, when painted and fitted with polished aluminium finish details are indistinguishable from the working item.

Dedicated Programme Management

A secure, confidential office is available for the discussion of your project at all stages.

Individual Managers (Tool room, Machine Shops, Pattern Shop, Model Shop) are in day-to-day control of operations, in addition to which our Senior Programme Manager maintains an overview of progress and quality issues in respect of each individual project.

Design and Engineering

Our CAD Engineers operate multiple seats of industry leading software including:

- Catia V5

- Siemens NX

- SolidWorks

- Creo

- Autodesk/Delcam

We have data acceptance in all formats with many years accumulated experience of Tool, Mould and Fixture design. We also have secure data transfer available.

Ask The Technical Experts

Book your FREE advisory consultation today.

If you’d like to discuss your most challenging engineering and design part or project, with a vastly experienced senior Alphateq engineering specialist, we invite you to book a FREE no-obligation confidential consultation with any one of the following…